Compact Spinning, Siro Spinning, Compact-Siro Spinning… As a fashion professional, do you often hear these terms?

Yarn is divided into different qualities and different spinning processes. Today, let’s talk about these processes, what they mean, and their characteristics.

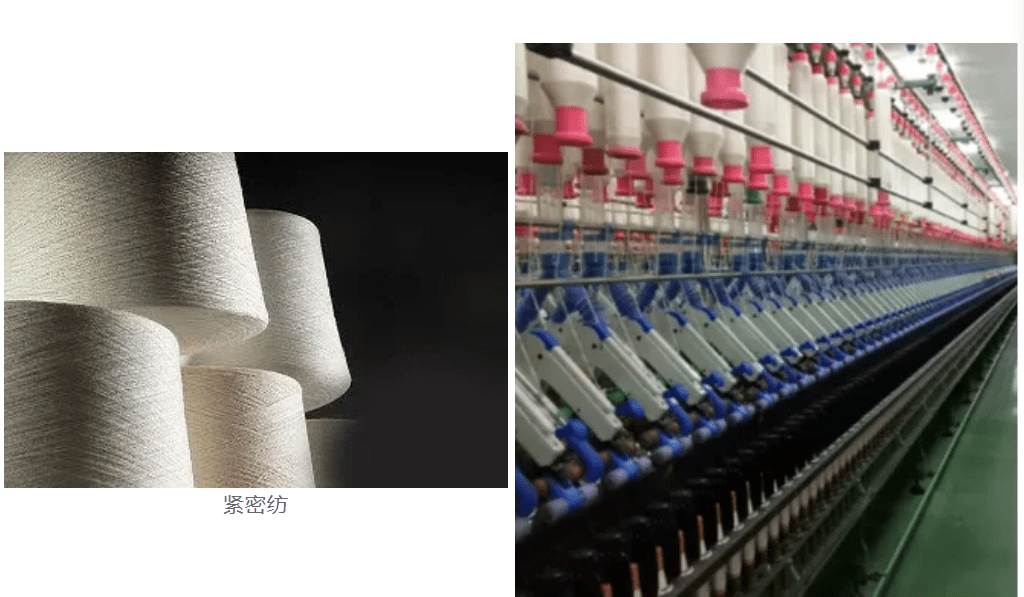

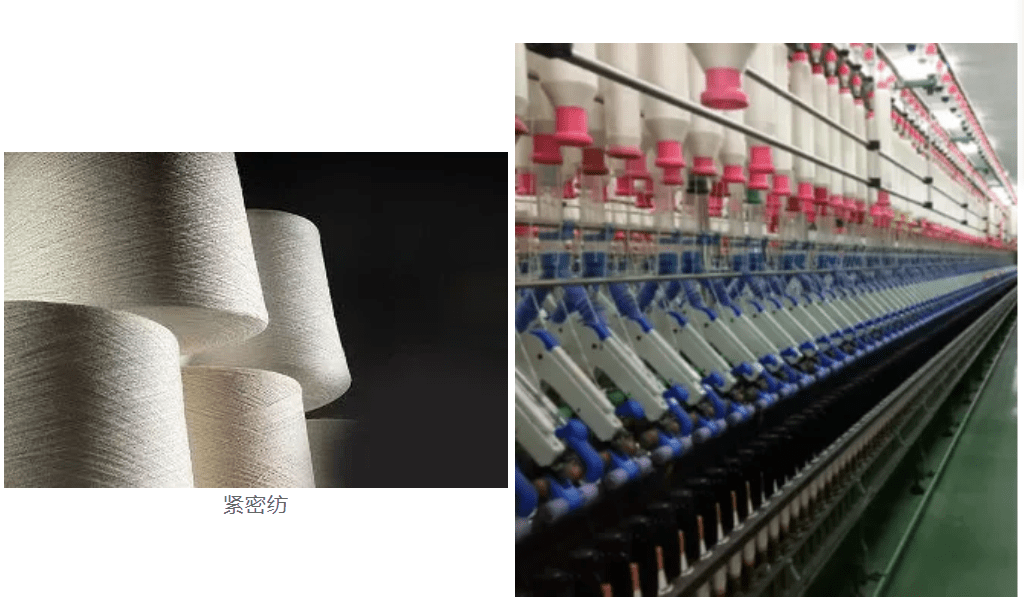

What is Compact Spinning?

Compact Spinning is a new spinning technology that operates on an improved ring-spinning frame. The main spinning mechanism is: an additional fiber condensing zone is added in front of the drafting system of the ring-spinning frame, essentially eliminating the spinning triangle between the front roller and the twisting point. After the fiber strand is delivered from the front roller, it first passes through a mesh apron on an air suction tube. As the strand moves on the mesh apron, the airflow condenses and contracts the fibers, making the fiber strand gradually turn from a flat strip to a cylindrical shape, and the fiber ends are twisted into the yarn. This results in a very compact yarn with a smooth surface and minimal fuzz, which makes it less prone to pilling during weaving.

Compact Spinning

The purpose of Compact Spinning is to make the fibers as parallel and close to each other as possible before twisting, which is a key criterion for high-quality compact yarn. The advantage lies in ensuring the fibers are parallel and consistent before twisting.

Advantages of Compact Spinning:

- Very little fuzz on the yarn, especially with minimal fibers over 3mm, which also improves loom efficiency and fabric smoothness.

- Strong cohesion between fibers, resulting in high yarn strength.

- Better evenness and fewer imperfections in comparison to traditional yarn.

However, Compact Spinning equipment is expensive, increasing the investment for spinning mills. Although the fuzziness is greatly reduced, other yarn properties such as evenness and imperfections are not significantly improved.

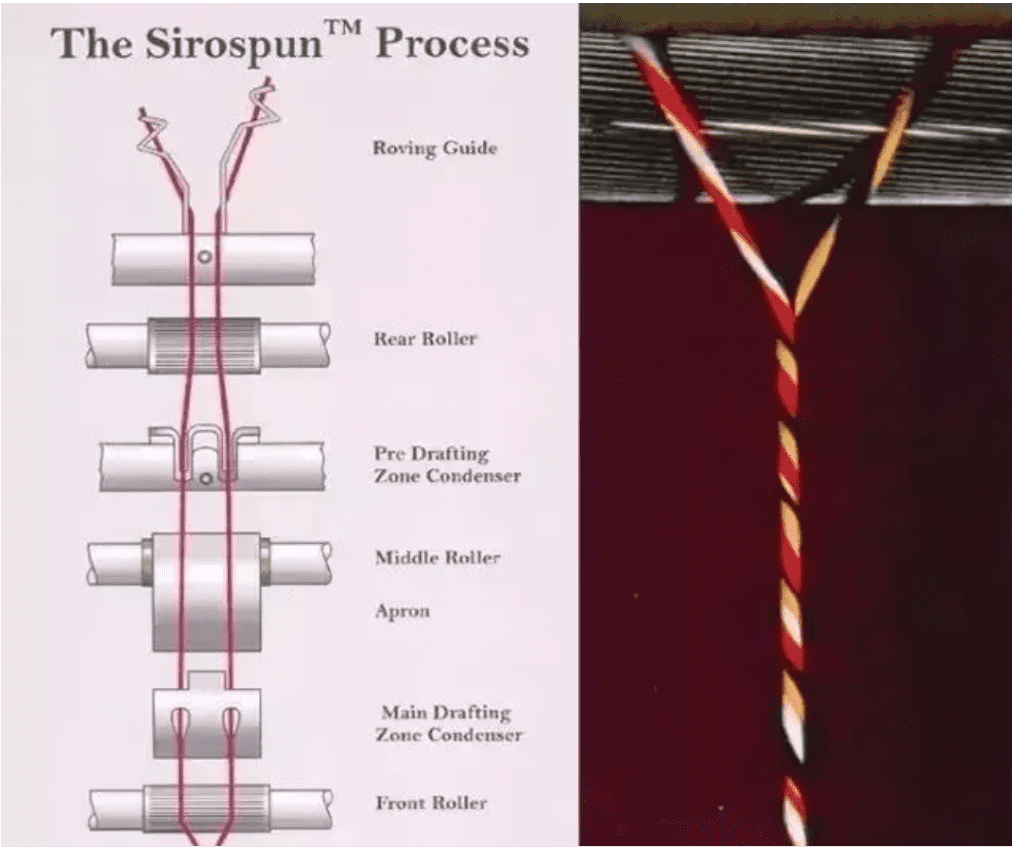

What is Siro Spinning?

Siro Spinning, also known as plied yarn spinning, is domestically referred to as A/B yarn and was later officially named Siro Spinning.

Siro Spinning uses two rovings fed into the spinning frame, keeping them parallel and at a certain distance from each other. In the drafting zone of the spinning frame, the two rovings are drafted in parallel by the rollers. At the front roller nip, two small triangular zones are formed before they are twisted together into a single yarn.

Due to the transmission of twist, the two strands already have some twist before they are fully combined, giving the final yarn a distinct plied structure compared to a regular single yarn. If colored rovings are used, it can produce a patterned “AB” blended yarn.

Siro Spinning Diagram

Characteristics of Siro Spinning:

Less fuzz, higher strength, and better abrasion resistance, making it suitable for weaving single yarns without sizing, and achieving lightweight wool fabrics.

Although Siro Spinning offers improvements over similar conventional yarns, there is still a way to go before it can be used for weaving single wool yarns without sizing. The wool industry has mostly abandoned this method, but it is still used in blends like T/C and CVC because it can produce a marled effect after dyeing, with a soft hand feel, good abrasion resistance, and breathability.

What is Compact-Siro Spinning?

Compact-Siro Spinning is a combination of Compact Spinning and Siro Spinning techniques.

Two rovings are fed in parallel at a certain distance through the same drafting system of the ring-spinning frame, and are drawn out simultaneously in parallel. After being held by the front rollers, they enter a pneumatic condensing zone. The surface of a special tube with dual slots, which are under negative pressure, is covered with a mesh apron. The mesh apron is driven by friction from the delivery roller.

The two fiber strands output from the front rollers are sucked onto the mesh apron’s surface, corresponding to the dual slots, and are condensed while moving forward with the apron. The condensed fibers gain a more compact structure, are lightly pre-twisted separately, combined at the point of convergence, and then further twisted and wound onto the yarn package, forming a yarn with a structure similar to plied yarn.

Characteristics of Compact-Siro Spinning:

Compact-Siro Spinning combines the characteristics and qualities of Compact Spinning and Siro Spinning. Compared to the other two processes, Compact-Siro Spinning significantly reduces fuzz, especially long fuzz, which can be almost completely eliminated. The synchronized twisting in the same direction makes the yarn structure more compact and clear, with a rounder cross-section and neatly aligned fibers on the surface. Compared to regular ring-spun yarns, Siro yarns, and Compact yarns, Compact-Siro yarns exhibit superior qualities.

Recommended Compact-Siro Spinning Products

Compact-Siro Spinning is an ideal material for producing high-end fabrics. The resulting fabric is less prone to pilling and fuzzing, has a cleaner and more defined surface, and offers good drapability and dyeing properties.